Hot Swap Fans

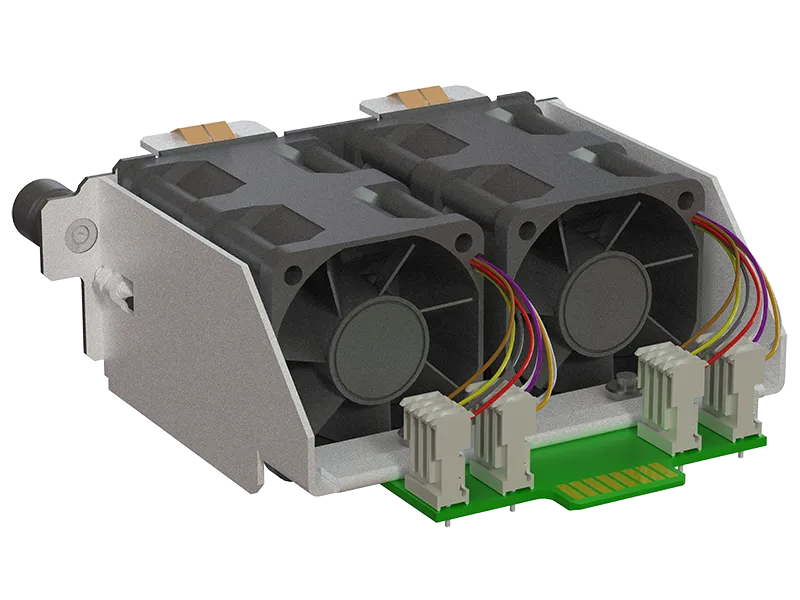

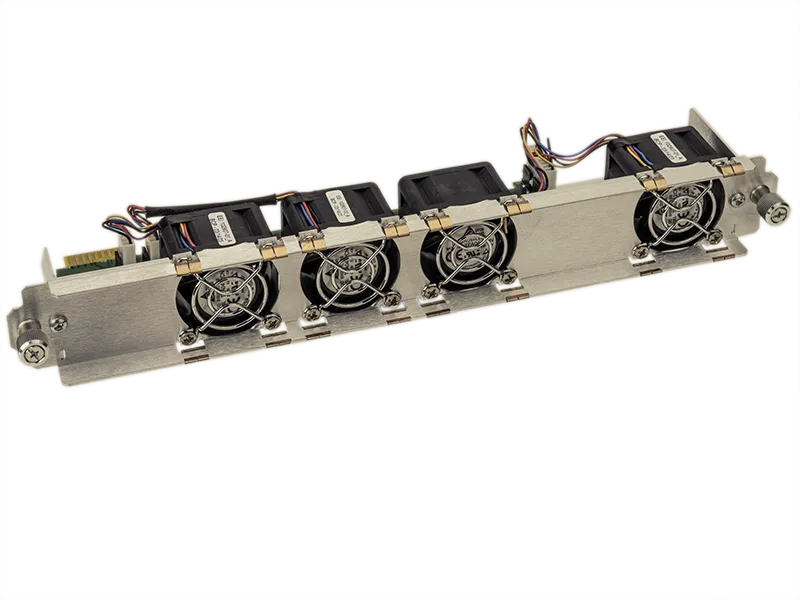

Not all rack mount data center appliances have fault tolerance or fail-safe requirements. Hot swap fan modules are a fast, easy solution when you need simplicity for maintenance without taking your system offline. In 10 seconds, you can replace the hot swap fan module or FRUs (Field Replaceable Units). Each fan module is custom-designed specific to the chassis we design and build for you. It needs to blind-mate dock with your motherboard or backplane. Unlike COTS hot-swap power supplies, an interposer is rarely necessary.

We control the module design specific to your rack mount system. During design, we raise or lower the connector to precisely align with the connector on your system board. We fabricate and assemble your rack mount enclosure and any FRUs, such as the hot-swap fan module as an integral set. Any module can consist of one or more fans.

Hot-Swap Fan Options